Product search

Featured Categories

Best sellers

K2 THERMAL INSULATED THERMAL INSULATED BOTTLE 650ML.

Price Range: £15.00 to £21.99

20MM RECYCLED PET DYE SUBLIMATION PRINT LANYARD.

Price Range: £0.40 to £0.74

24CM WOOD & OPTICAL CRYSTAL SQUARE COLUMN AWARD.

Price Range: £30.00 to £74.99

ECO 3 BATON BOX - DARK VEGAN BAR.

Price Range: £0.75 to £1.49

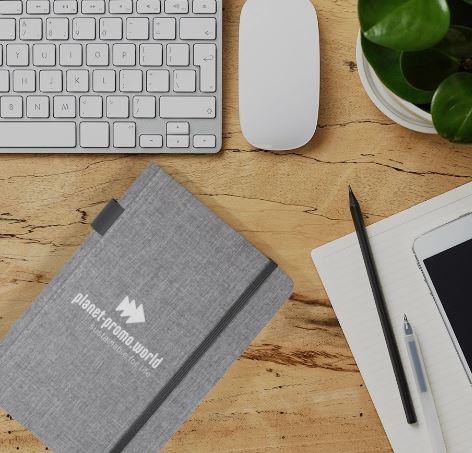

DOVER A5 ECO RECYCLED NOTE BOOK.

Price Range: £1.50 to £2.99

ALATA 8000 MAH BAMBOO SOLAR POWER BANK in Beige.

Price Range: £22.00 to £29.99

Frequently Asked Questions

How do we know products are really sustainable?

This is such an important question! Just calling something ‘eco’ or wrapping it in a bamboo veneer doesn’t make it sustainable. The are 5 main factors that determine sustainability:

- Materials

Are the materials used from renewable sources? Can they be recycled at end of life? - Production process

What certification supports the manufacturing process? - Durability

Will the products have a worthwhile lifespan, be appreciated and valued by recipients and are they well enough made to see out their time? - Disposal

Is it clear what the best form of disposal is and can the materials be reused? Ridiculously, there is no national policy on this, so individuals have to check their local regulations but thinking about this when purchasing can increase the likelihood of materials being reused.

There is a lot of ‘green washing’ about so it important to talk through the products you are interested in, ensure you are happy with any information provided and take nothing at face value. It is a battle we fight every day, especially when dealing with new manufacturers. One of the advantages of our 20 years of experience is that we have built excellent relationships with the best and most environmentally aware suppliers and know which companies are pushing ahead fastest with environmental initiatives. But let’s be clear – virtually NOTHING is truly sustainable, with the honourable exception of our Company Forest page. Sustainability is a journey we are all on and rapid and beneficial changes are happening in our industry. There are those who simply use it as a marketing tool and those who truly espouse the values of sustainability. We work exclusively with the latter group and we are committed to ensuring you have all the information you need to make informed choices.

What are your minimum quantities (MOQ)?

This is impossible to answer in a catch-all way. It just all depends. For some items it is 1, but for others it may be 100 or 1000. As a rule, the cheaper an item is, the more likely the MOQ will be high. But other factors come into play.

Small orders in a print facility geared to mass production are very disruptive. The time it takes to set very expensive equipment up to print 1 item is the same as it takes to prepare to print 1 million. So there is a fixed charge to set up the equipment and there will often be a minimum print charge too and this means that it may cost you oerhaps £100 just to print one item plus the cost of the item itself and courier charges. A £2 item can end up costing £120"

So minimum order quantities are set to offer best value. They vary from item to item and manufacturer to manufacturer and even when a MOQ is quoted, some manufacturers may produce fewer, but will apply a "less than minimum" charge. This is effectively another way of describing a minimum print charge.

So you answer your question, the best thing to do is ask.

What are your lead times?

This is another question where the only answer is "it depends"!

Most items are stocked and printed in the UK and are available within 10-15 days from artwork approval. That phrase is important because, even if you order something on a Monday but don't approve the pre-production proof until the Friday, the job will only then get added to the production schedule at that point.

Other items are printed abroad and so the additional transport time increases the time it will take to arrive with you. A few items are made entirely to order and so extra time will be taken to make the required tooI. For very large and entirely bespoke orders made overseas, it may make sense for the goods to be shipped by sea and this can result in leadtimes of up to 16 weeks from order to delivery.

But our industry is very mindful of deadlines and every effort will be made to meet them. Very occasionally a supplier might agree to a deadline but ask for an express fee because they need to rearrange the schedule and/or get staff work overtime. But whatever the position, he important thing is that you disclose your desired timescale at the earliest possible point.

Can we get a sample before ordering?

This is usually possible, though they will not always be FOC. Expensive items in particular are chargeable, although they are often available on a sale-or-return basis. Some items, for example clothing, are subject to a restocking charge and items will only be accepted back if received in good condition.

Please note that samples cannot be supplied with your own logo on.

Can you explain the artwork and print terms?

ARTWORK FILES

There are essentially 2 kinds of artwork files we can work with, depending on the decoration method used. These are:

- Vectorised graphic files

These will be files created in professional drawing packages like Adobe Illustrator and will be .EPS file types or editable PDFs. Vectorised simply means that the blocks of colour and their locations are defined mathematically, as on a graph.

If you don't have the right software, you won't be able to create or even open these files. Typically your designer can create these for you or you can ask us to help.

IMPORTANT: if you are sending us a vectorised graphic, you should ensure that any text is 'saved to outlines'. Outlining means that, instead of text being still editable, an image of the required text is provided. If not outlined, the file contains information saying 'here is text and it should be in the XYZ font'. But if our system hasn't got the XYZ font, it will have to substitute it with the default font and so your artwork will look different. Outling text prevents this. - Bitmap images

Bitmap images are made up of lots of small squares of colour called pixels. The number of pixels are measured in DPI or dots per inch. The more pixels, the higher the resolution of the image. Obviously high resolution images are better for print so a minimum of 300dpi is required.

Photos are bitmaps. If you zoom in on a bitmap, especially around the edges you will see that even apparently solid blocks of colour are made up of many shades of that colour. This means that bitmap images are only suitable for CMYK printing methods, such as litho and digital print,

It is possible to mix vectorised artwork with bitmaps. You might do this on larger format items such as cards, leaflets, brocuhure or banners. But the rules above remain the same.

PRINT METHODS

There are an ever-increasing number of ways of decorating items. Here are some YouTube links to demonstrate some of them (apologies for ads!)

- Engraving or etching

Etching is scratching the design into the surface of an items and is typically used on metal, crystal or glass items. But laser engraving can be used to. This burns the surface of the object (wood and other materials also) and leaves and indelible mark. Also formos of engraving or etching are mono and the colour left will depend on the material, the substrate and the equipment used. - Embroidery

Embroidery is used on fabrics and is a multicolour process using Madeira threads. There are hundreds of these so a very close colour match is possible but not pantone matched. Text to embroider should be al least 5mm wide and ideally serif fonts are best avoided, especially on small letters. Embroidery is priced by stitch count. - Screen Print

Screen printing is a very old, effective and cheap way of printing suitable for larger volumes and requiring a flat surface to print on. A messh with many wax filled holes has a design 'burned' into it (melts the wax) and it is mounted into a frame. The frame is filled with ink, laid on the surface to be printed and a blade then pushes the ink through the holes. If more colours are required, the process is repeated. A straight sided pen or mug, although curved, can still be screen printed as they can be rolled along beneath the screen. Screen printing is suitable for spot colour printing - Pad or Tampo Print

Pad printing is also used for spot colour printing, but only when the curface is curved or when access to part of the flat surface is restricted. A pad is just that. It picks up colour from a 'well' of ink shapped as required by the design, and then stamping it onto the surface of the target item. As the pad is soft, it bends round the curvature of the surface leaving the design behind. As with screen printing, if more colours are required, the porcess is repeated. There are limits to the curvature that can be printed. If it is too great, the design will distrort at the edges. - Digital Print

Probably the easiest to understand, digital print is like an inkjet printer. The whole design is printed in one go and the inks blended to create tones and gradient of colour. The limiation of digtial printers currently is that they need a flat surface. - Sublimation print

Sublimation (or heat transfer) print involves printing a design to a specially treated paper or film and then laying on the target object and applying heat and pressur. The heat cause the colour moleculs to be released onto the target surface. It is a full colour process and produces especially bright abd vobrant colours and photographic images. - Transfer print

There are loads of different transfers. With clothing, transfers can be used to apply metallic foil, rhinestones and other effects, but more commonly they are used to print images or designs. Once the transfer has been printed, it is applied to the target surface and bonded to the surface with heat (and often pressure. In this process the unprinted parts of the transfer burn avay leaving just the design. In ceramics, transfer is used (and applied by hand) to surfaces that would otherwise be unprintable.

COLOURS

- full colour print, which is a CMYK print process rather like the office inkjet printer. Colours can be blended to make tones and gradients as below but in order to achieve the desired effect.

Most files are suitable for full colour printing, including bitmaps (see above). - Spot colour print, which is exclusively solid blocks of colour. The "blocks" can be quite fine and small (eg the dot on the letter i), but they have to be all or nothing - ie blue will be 100% and not blue fading out to white.

Each colour is printed one after the other, so printing 1 colour is cheaper than 2. To print spot colours, pantone references are needed.

Engraving, foil blocking, debossing all count as

To print spot colours we need vectorised artwork (see below).

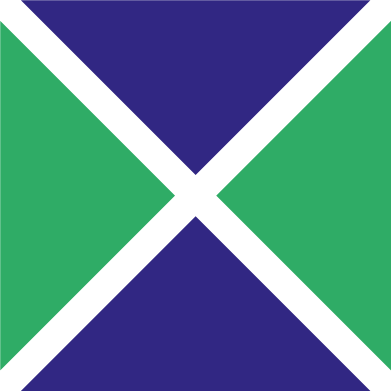

Spot colours are printed one colour at a time and, dependng on what item is being printed, the registration of the colours (meaning how they line up next to each other) can be an issue. In the example above, the registration is 'tight', meaning the colours abutt up to each other and this can cause problems if the print equipment has the tendency for 'movement'.

In the example below, there would be no registration issues as the colours don't touch

- Decoration

Most items are decorated using one of the above methods, but some items might use two or more decoration methods. Cloth is ofter embroidered to the left breast but printed to the reverse.

The decoration method will determine the way the artwork has to be presented.

If you have any doubts about this, just ask, We can help, including entirely redawing a design where the original files have been lost

What if you miss a deadline?

If you have an immovable deadline, it is important that you communicate it at the earliest possible moment. Once we give you a commitment to delivery by a certain date, we will do everything in our power to meet it. We don't fail, but there are certain aspects that are beyond our control especially with couriers being under intense and increasing pressure. It is always best to allow yourself plenty of time.